Yz Model Submersible Pump for Efficient Suction of Mud, Sand, and Corrosive Liquids in Various Industries

Basic Info.

| Model NO. | YZ |

| Working Pressure | High Pressure Pump |

| Influent Type of Impeller | Single Suction Pump |

| Position of Pump Shaft | Vertical Pump |

| Pump Casing Combined | Horizontal Split Pumps |

| Mounting Height | Suction Centrifugal |

| Impeller | Closed |

| Usage | Pump, Pumps |

| Submerged Length | 800-2000mm |

| Optional | Suction Tubes |

| Customized | Ss for Chemical Industry |

| Struture | Cantilever Type |

| Transport Package | Wood Case |

| Trademark | BLOSSOM |

| Origin | China |

| HS Code | 8413400000 |

| Production Capacity | 300set/Year |

Product Description

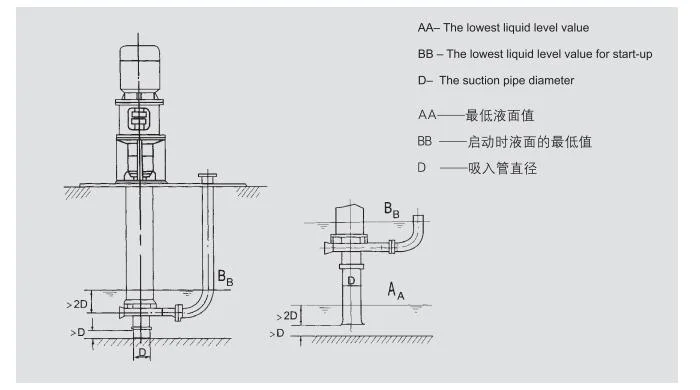

Product Description1)YZ Model Submersible Slurry Pump is a vertical but only suction cantilever centrifugal pump structure. The impeller is a semi-opened vane, and stirring blades are provided at the extension of the suction side of the impeller.

Two series of pumps are mainly used in environmental protection, municipal engineering, thermal power plants, gas coking plants, oil refineries, steel mills, mining, paper industry, cement factory, food factory, printing and dyeing industries to suck thick liquid, heavy oil, oil residue, dirty liquid, mud, mortar, sand and urban sewage drains flowing sludge, as well as liquid containing coal ash slag. Can also be used as a chemical, pharmaceutical and other industries suction containing mud and sand slag fluid and corrosive liquid.2) Model significance80 YZ 80 - 20AYZ- Submersible Slurry Pump (mortar pump)80 pump outlet diameter (mm)80- pump design point flow (m3/h)20 pump design head (m)A - indicates that the impeller has been cut for the first time3) The transmission mode of the pump: the pump is connected with the motor through the elastic coupling, and the pump rotates clockwise from the direction of the prime moverYZ pump is a single counter-level, single suction cantilever structure, with bearing seat, supporting seat, connecting pipe connected hydraulic parts of the pump, the liquid is discharged from the liquid pipe components, the impeller of the pump is a semi-opened impeller, impeller blade inlet extension is provided with mixing blades, the main characteristics of the pump is in the liquid part of the pump shaft, there is enough stiffness, impeller, pump shell between the bearing, do not use shaft seal, A medium containing a larger concentration of fixed particles can be transported. The length of the pump under the liquid insertion is between 800-2000, with suction pipe if necessary. The shaft seal uses a larger pump inserted into the liquid operation, without shaft seal, transmission by a vertical motor installed on the motor support and support seat, with a coupling connected to the pump.1. From the motor to the pump end, the pump is counterclockwise.2. The pump adopts long shaft structure, the insertion depth can reach 10 meters, the shaft connection structure is safe and reliable, and the disassembly is convenient.3. When the pump starts, the impeller is immersed in the medium, so it is easy to start, and there is no problem of exhaust pumping.4. Rotor parts can be axial adjustment, and the use of multi-point support, stable and reliable pump operation, can be used to lengthen the suction pipe, increase the insertion depth, make full use of their own suction process, the length of the rotor is shortened, rigidity is enhanced, life is prolonged, economic and reasonable.5. Sliding bearing can choose external cooling lubrication or self-cooling lubrication.6. The outlet flange is divided into half movable flange for easy connection.7. Equipped with low speed motor, low noise, stable operation, long service life.Structure declaration

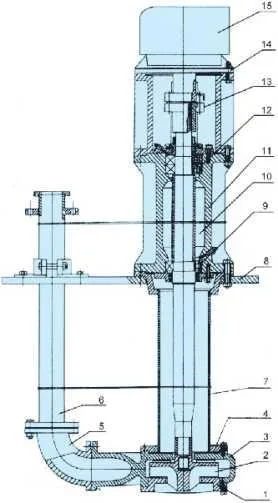

YZ pump is a single counter-level, single suction cantilever structure, with bearing seat, supporting seat, connecting pipe connected hydraulic parts of the pump, the liquid is discharged from the liquid pipe components, the impeller of the pump is a semi-opened impeller, impeller blade inlet extension is provided with mixing blades, the main characteristics of the pump is in the liquid part of the pump shaft, there is enough stiffness, impeller, pump shell between the bearing, do not use shaft seal, A medium containing a larger concentration of fixed particles can be transported. The length of the pump under the liquid insertion is between 800-2000, with suction pipe if necessary. The shaft seal uses a larger pump inserted into the liquid operation, without shaft seal, transmission by a vertical motor installed on the motor support and support seat, with a coupling connected to the pump.

| 1. Suction cover | 2. Impeller | 3. Pump body |

| 4. Pump cover | 5. Outlet elbow | 6. Outlet tube |

| 7. Connect tube | 8. Support pedestal | 9. Bearing |

| 10. Shaft | 11. Searing pedestal | 12. Bearing |

| 13. Bearing unit | 14. Motor support | 15. Motor |

| Flow capacity | Up to 550m³/h |

| Head | Up to 70m |

| Rotate speed | 1000-1500rpm |

| Efficiency | 40%-80% |

| No | Mark | Code | Using medium |

| 1 | F30%CrMo | Cr30A | It is the ideal material with 35% solid content of corrosive media, such as benzene phosphate slurry, limestone gypsum slurry and other corrosive media. |

| 2 | Z3CNUD26.05N | 2605N | Comparable to CD4MCuN, about 30% solid content corrodes abrasive media, such as phosphoric acid filtrate, limestone gypsum grout, etc. |

| 3 | 00Cr25Ni7Mo3N | 2507 | Similar to CD4MCu, containing about 30% solid corrosion abrasive media, such as phosphoric acid filtrate, limestone gypsum slurry and other stations. |

| 4 | 00Cr22Ni5Mo3N | 2205 | Similar to CD4MCU, containing about 30% solid corrosion abrasive media, such as phosphoric acid filtrate, limestone gypsum slurry and other stations. |

| 5 | Z180C13 | DF2 | The abrasive medium containing 70% solid content is the ideal material for slurry pump and mud pump. |

| 6 | lCrl8Ni9 | 304 | Dilute nitric acid, organic acid. |

| 7 | 00Crl8Ni9 | 304L | Dilute nitric, phosphoric, organic acids. |

| 8 | 0Crl7Nil2Mo2 | 316 | Dilute nitric, phosphoric, organic acids. |

| 9 | 00Crl7Nil4Mo2 | 316L | Various concentrations of sulfuric acid below 70°C, resist intergranular corrosion. |

The distribution of solid particles in the pipe (generally referred to as horizontal pipe) becomes more and more uneven as the average velocity of slurry decreases. When the velocity decreases to a certain value, a fixed or sliding bed surface appears at the bottom of the pipe. The velocity at which the particles begin to form a bed is called the sedimentation velocity. Since water is the commonly used transport fluid, it is usually turbulent under normal pipe flow conditions, so the flow mode of heterogeneous suspension under silting velocity is almost turbulent. It is directly related to the settling velocity of particles and the turbulence degree of the system, so it increases with the increase of particle size, particle mass and solid content. The importance of siltation velocity to pipe flow is obvious and it is the lower limit for safe operation. If the flow rate is lower than the silting rate, a bed of solid particles will form in the pipe, resulting in increased friction loss and often pulsating, and even blockage of the pipe. In order to ensure the normal flow of slurry in the pipeline, the velocity must exceed a given minimum value, which is called the critical settling velocity. Generally, the critical settling velocity is greater than the sedimentation velocity.

Detailed Photos